Hello to all…

My screen has been broken and not working anymore. Only a weak voice…

I connect 5v power to it, but the AMS1117 chip getting very hot.

I changed it, but it still getting very hot.

I measured its output but its not giving 3.3v. I got changing outputs between 0.8v to 2.2v. By the way the power supply hits to 1A…

I searched youtube and find a video that mention about U4 which my equivalent is IL6MH.

Than I searched for IL6MH but nothing found.

What was that chip is used for?(I think its regulator too. For finding its equivalent I need its specs)

Or do you have any advise for repairing my screen?

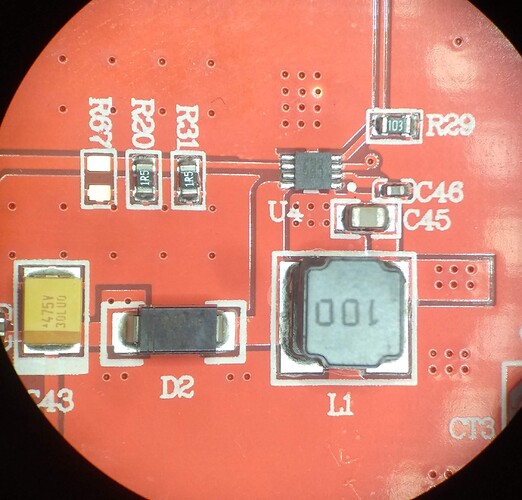

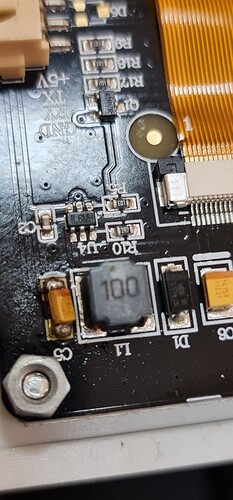

Does the chip look like this (U4 in the photo)? Next to it is the inductance Lx and the diode Dx? Then this is a boosting DC-DC (most likely to power the backlight LEDs, judging by the thickness of the tracks going to the display). I could not find a specific name for the marking. You can try to just unsolder this chip, turn on the display and see if the AMS1117 will get warm. If the problem is in this chip, then the display should work, just without backlighting or with very weak backlighting.

This is MP3202 Boosting Backlight LED Driver - https://www.monolithicpower.com/en/documentview/productdocument/index/version/2/document_type/Datasheet/lang/en/sku/MP3202/document_id/1495/ . You can also unsolder it and try to turn on the display, see if something will get warm without this microcircuit. If the problem is in it, then the display should work, and you can even see the image on it with a flashlight, but very weakly ![]()

Apparently, this microcircuit is also in my photo, but in a different, more powerful case (I have a 10.1" display).

First of all thanks for your interest.

Even though I unsolder IL6MH and checked the AMS1117 were still getting warm.

Then I changed the AMS but the newer one were also getting warm (while there were no IL6MH on the board).

Do you suggest any other operation ? ![]()

Badly. So the power supply is short somewhere else. If this happened to me, then the first thing I would do is look with a thermal imager at what else is warming up on the board except AMS1117. On a thermal imager, you can usually even see a path along which a significant current flows. In the absence of a thermal imager, you can try to feel everything with the back of your fingers (it is usually more sensitive to temperature than the fingertips). If it is not possible to find what is heating up, then it remains only to unsolder all the chips one at a time, starting with small ones, and turn it on to see if the heating of the AMS1117 has stopped.

No other ideas unfortunately ![]()

My advice: Trash it and buy a new one. If you spend more than one working hour diagnosing without coming closer to a solution, you are already at loss.

Shurik, these are not our methods.(с)

The NX848K050_11 costs 70$. What das your working hour (as an engineer, I guess) cost?

It is impossible to recalculate everything into the cost of hours according to your working tariff scale. There are things like curiosity, interest, hobbies and many other things that people spend their time on and do not consider how much money they could earn during this time ![]()

@AndyBig do you happen to have a thermal camera? If not, you might try the Louis Rossmann certified ouchi test (a.k.a. touch everything with your fingers till you find the place that makes it smell good).

If it’s a clean short, meaning no power dissipated in the faulty part, you might just remove the regulator and apply 3.3V directly to the board (current limited!!). If this still doesn’t show a hotspot, you can use a multimeter to measure the voltage drop along the current path. Probe ground to power supply ground, probe plus stepping across the ground connections of all parts. the idea is that the highest voltage drop must be coming from the part that has the short (because that’s where the current is flowing through).

Again, I suggest looking for some of Rossmanns MacBook Repair videos about diagnosing a short circuit, he explains it pretty well.

My advice: Trash it and buy a new one. If you spend more than one working hour diagnosing without coming closer to a solution, you are already at loss.

If only people would apply the same rigorous math to development time - especially time required to make things work around Nextion limitations…

How comes that you have no issue recommending people to spend a couple hours more of their time to develop hacks around those limitations, while spending the same amount of time on hardware diagnose is wasted in your eyes?

Don’t get me wrong, the latter can be very true in productive environments, but the same holds true for the software side.

That aside, I can see a few good reasons for doing this sort of diagnosis and repair even if time/money counts. One might be to understand a failure mode of the product. If you understand it, you can prevent it in the future by fixing your circuit around Nextion. If the fault origin is on Nextion itself you can report it such that they can fix it - HAHAHAHA sorry, joking, unfortunately unlikely to happen. But at least you’d know what fails and can do cheap component replacements in the future instead of doing module swaps.

Not the path that makes Nextions pockets happy, but can be highly reasonable for the company using Nextion products - and it’s about the latter one, right?

The other case is simply time. It may be faster to diagnose and repair it than to wait for a replacement. Especially when converting time to money you need to factor in delivery times and then it may not be the cheapest option to order a new one. Of course, this depends on many factors (can I do something else in the meantime, can the project afford waiting x delivery days, …), but it’s at least not quite as simple as you’re describing it.

Kind regards,

Max

@Max Yes, I have an inexpensive thermal camera and if such a malfunction happened on my display, then I would use this camera first of all ![]() But the author of the topic most likely does not have such a camera, which is why I advised him to probe the entire board with the reverse side fingers, finding the heating component.

But the author of the topic most likely does not have such a camera, which is why I advised him to probe the entire board with the reverse side fingers, finding the heating component.